Inventure Engineering & Machine, LLC

ENGINEERING - DESIGN - CNC MACHINE

Our team has over 100 years of combined experience in engineering and manufacturing. Much of this experience is related to new product development, precision parts manufacturing, custom machine design/build, and semiconductor capital equipment.

Products

-

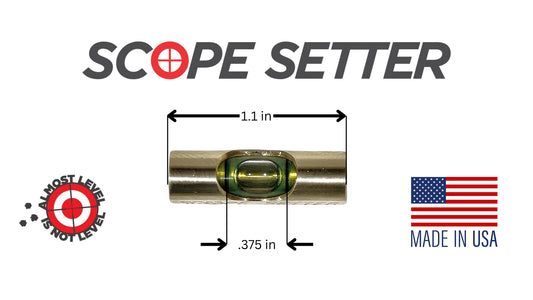

Replacement Level

Regular price $24.95 USDRegular priceUnit price / per -

Scope Setter 6

Regular price $119.95 USDRegular priceUnit price / per -

Scope Setter 8

Regular price $119.95 USDRegular priceUnit price / per